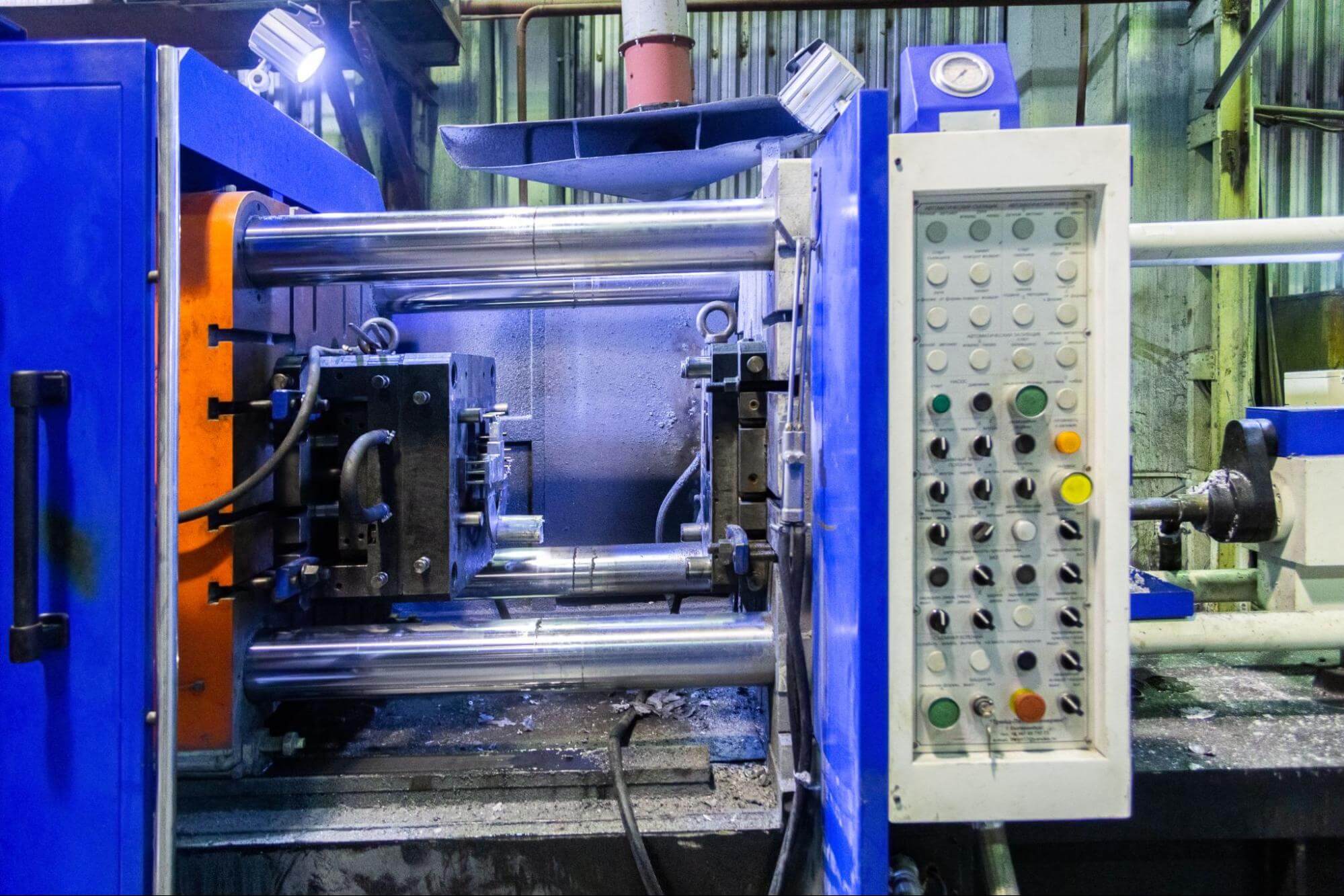

High-pressure die casting continues raising durability expectations across modern industrial production. The process enables manufacturers to achieve consistent strength while maintaining tight dimensional tolerances. Precision tooling, controlled injection forces, and disciplined thermal management elevate vietnam die casting within demanding manufacturing environments. These developments quietly reshape reliability benchmarks across automotive, energy, and infrastructure sectors.

Rising precision shaping industrial durability

High-pressure die casting improves durability through controlled metal flow and cavity filling accuracy. Molten alloys enter complex molds under calculated pressure, reducing internal inconsistencies. Uniform density strengthens resistance against vibration, pressure variation, and long operational cycles.

Material science strengthening component longevity

Modern alloy engineering enhances long-term structural performance under industrial stress. Refined aluminum and magnesium blends improve strength-to-weight ratios while maintaining thermal stability. Zinc-based alloys contribute to surface integrity and wear resistance. Controlled cooling techniques reduce porosity and microfractures that weaken components prematurely.

- Aluminum alloys optimized for thermal resistance

- Magnesium blends supporting lightweight structural strength

- Zinc formulations improving surface finish durability

- Copper additions enhancing mechanical fatigue thresholds

These material choices strengthen components exposed to constant operational stress. Maintenance cycles lengthen without compromising safety margins. Manufacturers gain confidence delivering long-lasting industrial solutions.

How does pressure control improve lifespan?

Injection pressure directly affects internal cohesion and density distribution. Stable pressure prevents air entrapment and uneven solidification within the mold. Uniform structures resist crack formation during mechanical or thermal cycling. Manufacturers adjust pressure profiles based on geometry and alloy behavior. Balanced control improves consistency across production runs. Component lifespan improves as internal stress remains evenly distributed.

Automation improving repeatability at scale

Automation reinforces durability by limiting variability during critical casting stages. Robotic handling ensures consistent mold transfer and metal delivery. Automated dosing stabilizes alloy volumes across repeated cycles. Integrated sensors monitor temperature and pressure in real time. These systems reduce human-induced variation during high-volume production. Repeatability strengthens confidence in large-scale durability outcomes.

- Robotic ladling ensuring accurate molten transfer

- Automated trimming reducing edge stress formation

- Sensor-guided cooling maintaining uniform solidification

- Programmable presses controlling injection parameters precisely

Automation supports predictable strength across extended production batches. Quality deviations decline as monitoring improves. Production scalability increases without sacrificing reliability.

Can automation reduce failure risks long term?

Automated monitoring identifies deviations before defects propagate internally. Early corrections prevent cumulative structural weaknesses. Production data enables proactive refinement rather than reactive inspection. Failure risks decline as processes stabilize over time. Manufacturers experience fewer performance-related disruptions. Long-term reliability improves through informed process control.

Regional expertise shaping durable manufacturing outputs

Manufacturing discipline and workforce expertise influence durability outcomes significantly. Southeast Asian facilities emphasize process control and consistency. Within this environment, vietnam die casting operations demonstrate reliable output supported by skilled technicians and modern equipment. Production strategies prioritize quality stability over excessive throughput. This approach aligns with global industrial durability expectations.

Expanding applications under demanding environments

High-pressure die casting supports applications requiring sustained structural reliability. Infrastructure components endure environmental exposure without rapid degradation. Energy systems demand resistance to pressure and temperature variation.

Automotive platforms rely on predictable strength for safety performance. Industrial machinery benefits from reduced downtime and longer service intervals. These advancements continue expanding high-pressure die casting adoption across critical industries.